by Robyn Bolton | Mar 4, 2025 | Automation & Tech, Leadership

Imagine a manufacturing company. On the factory floor, machines whirl and grind, torches flare up as welding helmets click closed, and parts and products fall off the line and into waiting hands or boxes, ready to be shipped to customers. Elsewhere, through several doors and a long hallway, you leave the cacophony of the shop floor for the quiet hum of the office. Computers ping with new emails while fingers clickety-clack across the keyboard. Occasionally, a printer whirs to life while forcing someone to raise their voice as they talk to a customer on the other end of the phone.

Now, imagine that you ask each person whether AI and automation will positively or negatively affect their jobs. Who will champion new technology and who will resist it?

Most people expect automation acceptance to be separated by the long hallway, with the office workers welcoming while the factory workers resist.

Most people are wrong.

The Business Case for Problem-Solving Job Design

Last week, I wrote about findings from an MIT study that indicated that trust, not technology, is the leading indicator of whether workers will adopt new AI and automation tools.

But there’s more to the story than that. Researchers found that the type of work people do has a bigger influence on automation perception than where they do it. Specifically, people who engage in work requiring high levels of complex problem-solving alongside routine work are more likely to see the benefit of automation than any other group.

Or, to put it more simply

While it’s not surprising that people who perform mostly routine tasks are more resistant than those who engage in complex tasks, it is surprising that this holds true for both office-based and production-floor employees.

Even more notable, this positive perception is significantly higher for complex problem solvers vs. the average across all workers::

- Safety: 43% and 41% net positive for office and physical workers, respectively (vs. 32% avg)

- Pay: 27% and 25% net positive for physical and office workers, respectively (vs. 3.9% avg)

- Autonomy: 33% net positive for office workers (vs. 18% average)

- Job security: 25% and 22% net positive for office and physical workers, respectively (vs. 3.5%)

Or, to put it more simply, blend problem-solving into routine-heavy roles, and you’ll transform potential technology resistors into champions.

3 Ways to Build Problem-Solving Into Any Role

The importance of incorporating problem-solving into every job isn’t just a theory – it’s one of the core principles of the Toyota Production System (TPS). Jidoka, or the union of automation with human intelligence, is best exemplified by the andon cord system, where employees can stop manufacturing if they perceive a quality issue.

But you don’t need to be a Six-Sigma black belt to build human intelligence into each role:

- Create troubleshooting teams with decision authority

Workers who actively diagnose and fix process issues develop a nuanced understanding of where technology helps versus hinders. Cross-functional troubleshooting creates the perfect conditions for technology champions to emerge.

- Design financial incentives around problem resolution

The MIT study’s embedded experiment showed that financial incentives significantly improved workers’ perception of new technologies while opportunities for input alone did not. When workers see personal benefit in solving problems with technology, adoption accelerates.

- Establish learning pathways connected to problem complexity

Workers motivated by career growth (+33.9% positive view on automation’s impact on upward mobility) actively seek out technologies that help them tackle increasingly complex problems. Create visible advancement paths tied to problem-solving mastery.

Innovation’s Human Catalyst

The most powerful lever for technology adoption isn’t better technology—it’s better job design. By restructuring roles to include meaningful problem-solving, you transform the innovation equation.

So here’s the million-dollar question every executive should be asking: Are you designing jobs that create automation champions, or are you merely automating jobs as they currently exist?

by Robyn Bolton | Feb 26, 2025 | Automation & Tech, Innovation

We’ve all seen the apocalyptic headlines about robots coming for our jobs. The AI revolution has companies throwing money at shiny new tech while workers polish their résumés, bracing for the inevitable pink slip. But what if we have it completely, totally, and utterly backward? What if the real drivers of automation success have nothing to do with the technology itself?

That’s precisely what an MIT study of 9,000+ workers across nine countries asserts. While the doomsayers have predicted the end of human workers since the introduction of the assembly line, those very workers are challenging everything we think we know about automation in the workplace.

The Secret Ingredient for Technology ROI

MIT surveyed workers across the manufacturing industry—50% of whom reported frequently performing routine tasks—and found that the majority ultimately welcome automation. But only when one critical condition is present. And it’s one that most executives completely miss while they’re busy signing purchase orders for the latest AI and automation systems.

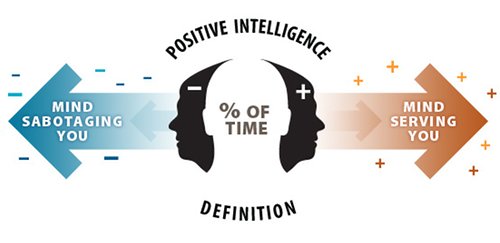

Trust.

Read that again because while you’re focused on selecting the perfect technology, your actual return depends more on whether your team feels valued and believes you are invested in their safety and professional growth.

Workers Who Trust, Automate

This trust dynamic explains why identical technologies succeed in some organizations and fail in others. According to MIT’s research:

- Job satisfaction is the second strongest indicator of technology acceptance, with a 10% improvement that researchers identified as consistently significant across all analytical models

- Feeling valued by their employer shows a highly significant 9% increase in positive attitudes toward automation

- Trust also consistently predicts automation acceptance, as workers scoring higher on trust measures are significantly more likely to view new technologies positively.

For example, Sam Sayer, an employee at a New Hampshire cutting tool manufacturer, has become an automation champion because his employer helped him experience how factory-floor robots could free him from routine tasks and allow him to focus on more complex problem-solving. “I worked in factories for years before I ever saw a robot. Now I’m teaching my colleagues on the factory floor how to use them.”

This contrasts with an aerospace manufacturer in Ohio that hired a third party to integrate a robot into its warehouse processes. Despite the company’s efforts to position the robot as a teammate, even giving it a name, workers resisted the technology because they didn’t trust the implementation process or see clear personal benefits.

These patterns hold across industries and countries: When workers perceive their employer as invested in their development and well-being, automation initiatives succeed. When that foundation is missing, even the most sophisticated technologies falter.

Four Steps to Convert Resistors to Champions

Whether it’s for the factory floor or the office laptop, if you want ROI and revenue growth from your automation investments, start with your people:

- Design roles that connect workers to outcomes: When people see how their input shapes results, they become natural technology allies.

- Create visible growth pathways. Workers motivated by career advancement are significantly more likely to embrace new technologies.

- Align financial incentives with implementation goals. When workers see the personal benefits of adoption, resistance evaporates faster than free donuts in the break room.

- Make safety improvements the leading edge of your technology story. It’s the most universally appreciated benefit of automation.

A Provocative Challenge

Ask yourself this (potentially) uncomfortable question: Are you investing as much in trust as you are in technology?

Because if not, you might as well set fire to a portion of your automation budget right now. At least you’d get some heat from it.

The choice isn’t between technology and workers—it’s between implementations that honor human relationships and those that don’t. The former generates returns; the latter generates résumé updates.

What are you choosing?

by Robyn Bolton | Dec 30, 2020 | Innovation, Tips, Tricks, & Tools

According to a 2018 survey by NPR and The Marist Poll, the most common New Year’s resolution is to exercise more. Not surprisingly, losing weight and eating a more healthy diet ranked third and further, respectively (“stop smoking” was #2, in case you’re curious).

Hitting the gym to drop weight and build muscle is a great habit to build, but don’t forget about the regular work needed to build other muscles.

Specifically, your innovation muscles.

Innovation mindsets, skills, and behaviors can be learned but if you don’t continuously use them, like muscles, they can weaken and atrophy. That’s why it’s important to create opportunities to flex them.

One of the tools I use with clients who are committed to building innovation as a capability, rather than scheduling it as an event, is QMWD – the Quarterly-Monthly-Weekly-Daily practices required to build and sustain innovation as a habit.

QUARTERLY

Leave the office and talk to at least 3 of your customers

It’s tempting to rely on survey results, research reports, and listening in on customer service calls as a means to understand what your customers truly think and feel. But there’s incredible (and unintended) bias in those results.

Take, for example, this story from former P&G CEO AG Lafley:

One very quick story; I will never forget this. We used to do annual research in the laundry detergent business, and every year consumers would rate the Tide powder cardboard package as excellent; excellent to shop; excellent for opening; excellent in use–on, on, on.

So, probably 27 or 30 years ago, I’m in basements in Tennessee, in Kentucky, doing loads of laundry with women, and after three or four or five of these one-on-one sessions, I’ve realized that not a single woman has opened a box of Tide with her hand. Why not? You’ll break your fingernails!

So, how did they open the box? They had nail files; they had screwdrivers; they had all kinds of things sitting down on the shelf over their washing machine, and yet they thought our package was excellent. And we thought our package was excellent because they were telling us our package was excellent. We had to see it and experience it.

Here’s the problem–consumers cannot really tell us what they want. They can tell you why they like it or why they don’t like it, but they cannot tell you what they want.

Schedule a day each quarter to get out of the office and meet your customers. Ask them what they like and what they don’t. More importantly, watch them use your products and then share what you heard and saw with your colleagues.

MONTHLY

Share with your team a mistake you made and what you learned from it

Silicon Valley mantras like “fail fast” and “fail often” make for great office décor but, let’s be honest, no one likes to fail and very few companies reward it.

Instead of repeating these slogans, reframe them to “learn fast and learn often” and role model the behavior by sharing what you learned from things you did that didn’t go as expected. You’ll build a culture of psychological safety, make smart risks acceptable, and increase your team’s resilience. All things required to innovate in a sustainable, repeatable, and predictable manner.

Do 1 thing just for the fun of it.

In the research that fed into their book, The Innovator’s DNA, professors Jeff Dyer, Hal Gregersen, and Clayton Christensen, found that the most common characteristic amongst the great innovators of our time was their ability to associate – “to make surprising connections across areas of knowledge, industries, even geographies” (page 41). Importantly, their associative thinking skills were fed by one or more “Discovery Skills” – questioning (asking “why,” “why not,” and “what if”), observing, experimenting, and networking.

Fuel your associative thinking ability by doing something NOT related to your job or other obligations. Do something simply because it interests you. You might be surprised where it takes you. After all, Steve Jobs studied calligraphy, meditation, and car design and used all of those experiences in his “day job.”

WEEKLY

Make 1 small change for 1 day

Innovation requires change and, if you’re an innovator, that’s the exciting part. But most people struggle with change, a fact that can be frustrating for change agents.

In order to lead people through change, you need to empathize with them and their struggles which is why you need to create regular moments of change in your work and life. One day each week, make a conscious change – sit on the other side of the conference room table, take a different route to the bathroom, use a black pen instead of a blue one. Even small changes like this can be a bit annoying and they’ll remind you that change isn’t always the fun adventure you think it is.

DAILY

Ask “How can we do this better?”

Innovation is something different that creates value. Which is good news because that means that all it takes to be an Innovator is to DO something DIFFERENT and create VALUE. The easiest way to do that is to find opportunities for improvement.

The next time you’re frustrated with or confused by a process, ask “how can we do this better?” Better can be more simply, faster, cheaper, or even in a way that is more enjoyable but, whatever it means, the answer will point the way to creating value for you, your team, and maybe even your company.

In closing…

Block time on your calendar for these quarterly, monthly, weekly, and daily habits. After all, the best reflection of your priorities are the things in your calendar. And, if you stick with this, you’ll be among the 8% who achieve their New Year’s goals.

Originally published on December 5, 2019 on Forbes.com